Thermal Shock Testing Experior Laboratories - Scope of work for electrical conductivity testing (figure 1): Figure 10 shows the triaxial test results of thermal shock hdr, including 20 data points with a confining pressure of 0 mpa. Thermal shock testing simulates extreme temperature fluctuations experienced by materials in various industries. Thermal shock testing subjects a product to extreme temperature changes within seconds to evaluate its structural. You should also read this: Emission Test Chicago Hours

Thermal Shock Testing Thermal Shock Test Laboratory Westpak - In contrast, temperature cycle testing features transition rates below 15°c per minute, typically ranging from 1 to 10°c per minute based on our experience. At nemko, we have extensive experience for performing thermal shock testing. Thermal shock testing subjects a product to extreme temperature changes within seconds to evaluate its structural integrity and performance under sudden thermal stress. Thermal shock. You should also read this: Crisis Prevention Intervention Test Answers

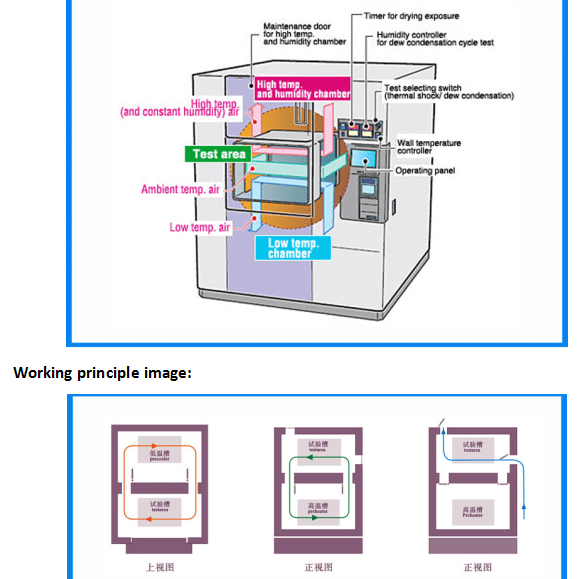

Thermal Shock Testing Temperature Cycling Delserro Engineering - To do this, two chambers are used at different temperatures, and the samples are quickly moved from one. Thermal shock is performed to determine the resistance of the part to sudden changes in temperature. Thermal shock testing simulates extreme temperature fluctuations experienced by materials in various industries. The heart of this testing is a device called a thermal shock chamber.. You should also read this: Gace Paraprofessional Practice Test Free

Two Zones Thermal Shock Test Chamber Thermal Shock Test Chamber - Thermal shock testing simulates extreme temperature fluctuations experienced by materials in various industries. It typically involves transferring a test sample between two or more chambers with drastically different temperatures. Both thermal shock testing and temperature cycle testing exposes a device under test (dut) to alternating high and low air temperatures to accelerate failures caused due to repeated temperature variations during. You should also read this: Emissions Testing East Hartford Ct

Thermal Shock Testing Keystone Compliance - The heart of this testing is a device called a thermal shock chamber. Thermal shock testing exposes products to alternating low and high temperatures to accelerate failures caused by temperature cycles or thermal shocks during normal use. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. In contrast, temperature cycle testing features transition rates below 15°c per. You should also read this: Test De Velocidad Etb

Thermal Shock Testing Sterling Performance - Thermal shock testing is a critical process in materials science, engineering, and quality control that evaluates how a material or component reacts to rapid temperature changes. Thermal shock testing subjects a product to extreme temperature changes within seconds to evaluate its structural integrity and performance under sudden thermal stress. Figure 10 shows the triaxial test results of thermal shock hdr,. You should also read this: Ambulance Driver License Test

thermal shock test, the key point for the thermal shock test - Tüv süd offers a range of thermal shock testing services, including cyclic temperature testing with transfer times of less than 15 seconds. The critical confining pressure coefficient η needs to be determined by the least square fitting of the triaxial test data of thermal shock dry hot rock. Scope of work for electrical conductivity testing (figure 1): The failure criterion. You should also read this: 3 Weeks No Period Negative Test

Thermal Shock EMC Technologies Accredited Product testing - At nemko, we have extensive experience for performing thermal shock testing. Thermal shock testing is performed to help determine the ability of electronic components to withstand rapid changes in temperature. Due to the extremely high rate of change of temperature, it is considered to be a severe test. To do this, two chambers are used at different temperatures, and the. You should also read this: Dosage Calculation 3.0 Pediatric Medications Test

Environmental Climatic Test Chamber / Thermal Shock Testing Equipment - Key parameters of thermal shock testing include: Figure 10 shows the triaxial test results of thermal shock hdr, including 20 data points with a confining pressure of 0 mpa. Such exposure will test the expansion rates of parts and components, the bonding strength of various materials. Thermal shock is performed to determine the resistance of the part to sudden changes. You should also read this: How Often Does Allied Universal Drug Test For Marijuanas

Hightemperature thermal shock test process Download Scientific Diagram - At its core, the thermal shock test submerges an item into extreme heat and cold to test its strength. Both thermal shock testing and temperature cycle testing exposes a device under test (dut) to alternating high and low air temperatures to accelerate failures caused due to repeated temperature variations during normal use conditions. Thermal shock testing is an accelerated environmental. You should also read this: Nj Mvc Appointment Driving Test