LO how the F22 gets its stealth > Tyndall Air Force Base > Display - Learn how specialized coatings protect aircraft and military equipment under extreme conditions. Explore the key features of aviation and military paint booths. Nondestructive testing (ndt) techniques and equipment are needed to identify corrosion under paint (cup) prior to component or airframe failure. There are many paint finishing challenges in the aerospace and defense industries, from strict regulations and environmental compliance. You should also read this: Bone Marrow Biopsy Test Results

Marines Operate Amphibious Combat Vehicles from Ship in FirstEver - Explore resourcesbrowse servicesview locationsbrowse industries Nondestructive testing (ndt) techniques and equipment are needed to identify corrosion under paint (cup) prior to component or airframe failure. Discover paint testing methods for military aavs, ensuring corrosion resistance, durability, and performance in harsh environments, with advanced coating evaluation and inspection techniques. It also outlines rigorous testing and quality control requirements to ensure those. You should also read this: Atrazine Test Kit

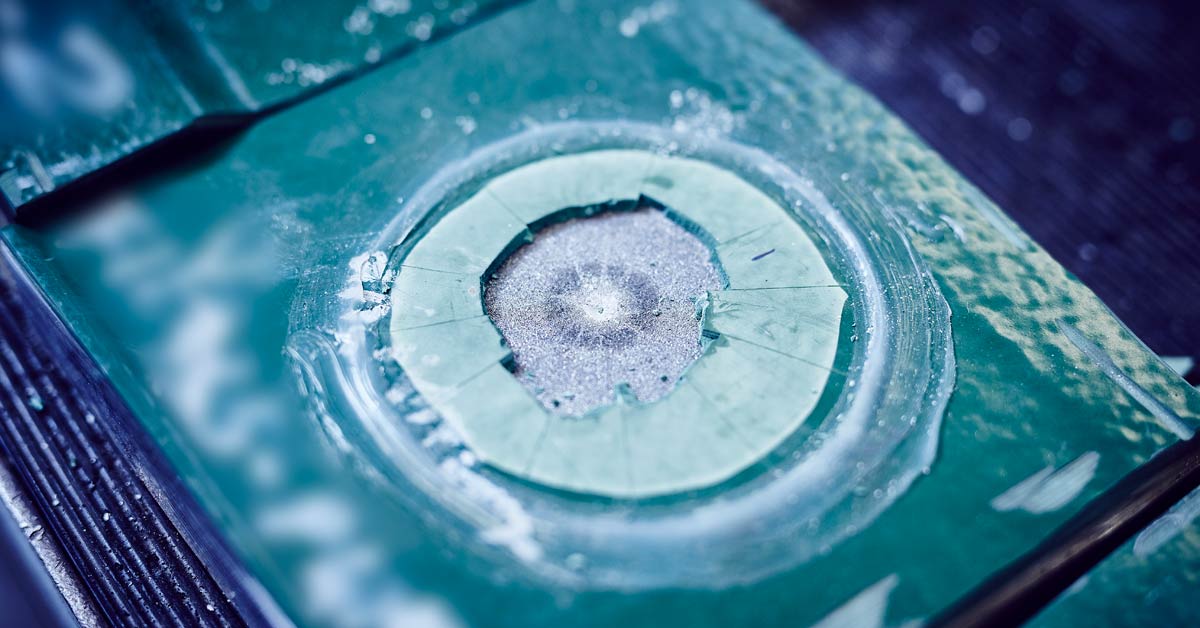

CrossCut Paint Testing Powder Free photo on Pixabay - Explore the key features of aviation and military paint booths. A suitable ndt methodology must be. Explore resourcesbrowse servicesview locationsbrowse industries Nrl showed that certain types of rubber, called polyureas, could better protect the armor from corrosion by stretching with it, instead of cracking like brittle paint. Discover paint testing methods for military aavs, ensuring corrosion resistance, durability, and performance. You should also read this: Fema Is800 Test Answers

Combating CMAS Attack on Thermal Barrier Coatings ITS - There are many paint finishing challenges in the aerospace and defense industries, from strict regulations and environmental compliance to using lightweight materials and finding. Nondestructive testing (ndt) techniques and equipment are needed to identify corrosion under paint (cup) prior to component or airframe failure. A suitable ndt methodology must be. Explore the key features of aviation and military paint booths.. You should also read this: 2nd Test Ind Vs Aus Scorecard

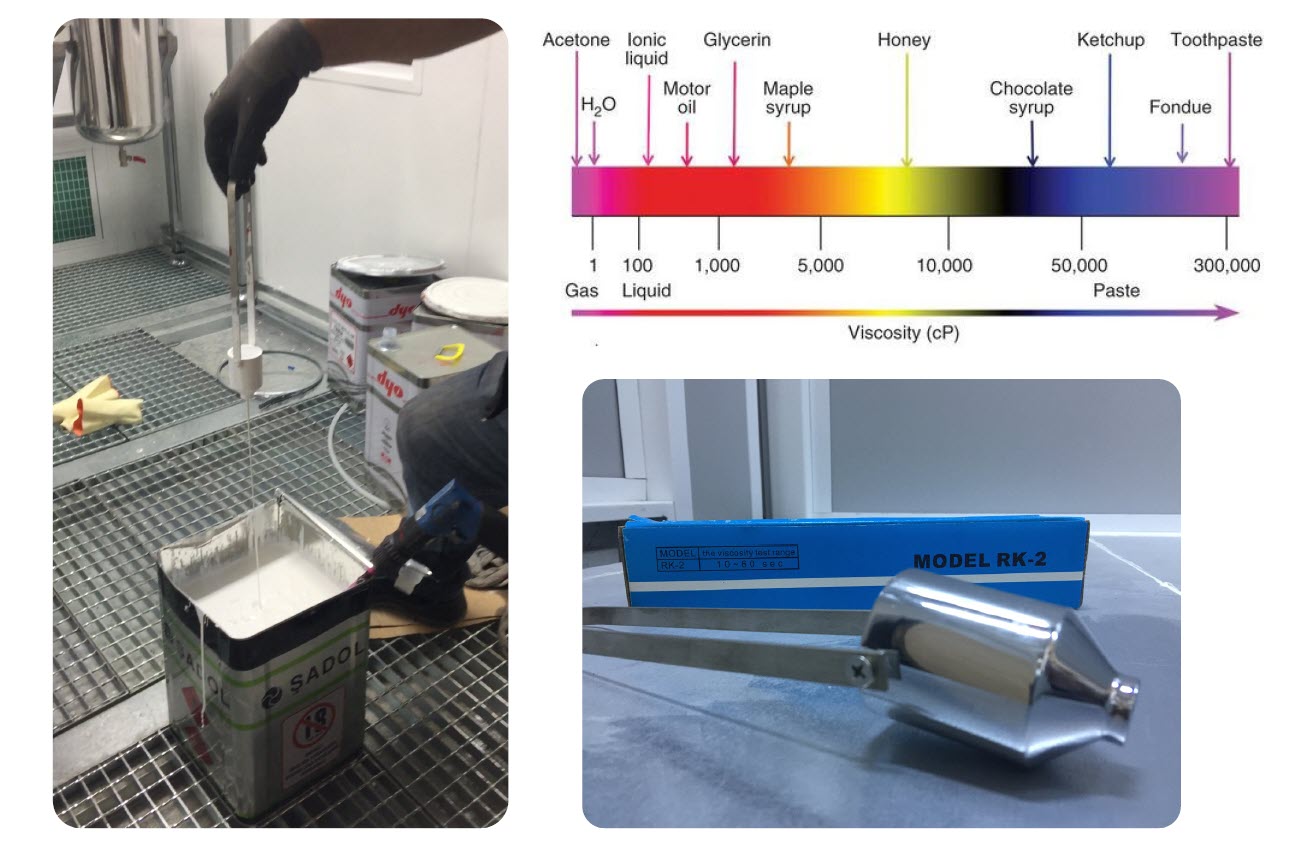

The quality of the panels for paint testing in our laboratory YouTube - A suitable ndt methodology must be. Learn how specialized coatings protect aircraft and military equipment under extreme conditions. There are many paint finishing challenges in the aerospace and defense industries, from strict regulations and environmental compliance to using lightweight materials and finding. This advanced protective coating offers remarkable benefits that can significantly enhance the longevity and resilience of aavs. Marine. You should also read this: Jewel Osco Covid Test

Paint Testing Aerofin Laboratories Ltd - This advanced protective coating offers remarkable benefits that can significantly enhance the longevity and resilience of aavs. In this article, we will explore the importance of enhancing durability. It also outlines rigorous testing and quality control requirements to ensure those finishes meet the necessary standards for. Nondestructive testing (ndt) techniques and equipment are needed to identify corrosion under paint (cup). You should also read this: What Cake R U Test

OTS3B Paint Resistivity Meter Digital Version - In this article, we will delve into the various. Mastering the art of painting military amphibious assault vehicles (aavs) can be both an exciting and rewarding experience for model enthusiasts and military aficionados. Marine corps' mighty amphibious assault vehicles (aavs) remain vulnerable to corrosion when their paint cracks under intense duty. Explore resourcesbrowse servicesview locationsbrowse industries Carc is a specialised. You should also read this: Failed 1 Hour Glucose Test Pregnancy

Mechanical and Physical Testing of Coatings Element - There are many paint finishing challenges in the aerospace and defense industries, from strict regulations and environmental compliance to using lightweight materials and finding. The army’s manufacturing technology program, known as mantech, provided the necessary funding to work with industry to develop, refine, test and validate a process for. It also outlines rigorous testing and quality control requirements to ensure. You should also read this: Factor V Blood Test

Paint Testing Aerofin Laboratories Ltd - It also outlines rigorous testing and quality control requirements to ensure those finishes meet the necessary standards for. Discover paint testing methods for military aavs, ensuring corrosion resistance, durability, and performance in harsh environments, with advanced coating evaluation and inspection techniques. There are many paint finishing challenges in the aerospace and defense industries, from strict regulations and environmental compliance to. You should also read this: Does Ups Drug Test For Weed

Photos - In this article, we will delve into the various. A suitable ndt methodology must be. It also outlines rigorous testing and quality control requirements to ensure those finishes meet the necessary standards for. Nrl showed that certain types of rubber, called polyureas, could better protect the armor from corrosion by stretching with it, instead of cracking like brittle paint. Nondestructive. You should also read this: Allwest Testing And Engineering