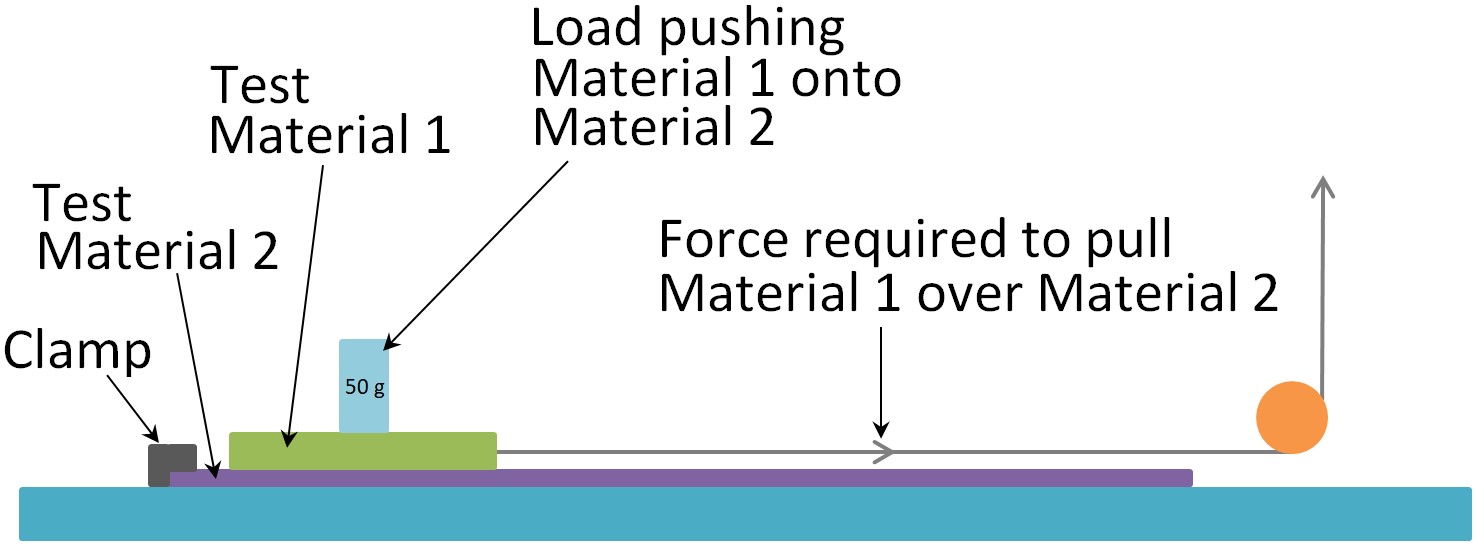

Schematic diagram of the friction testing. Download Scientific Diagram - Some common tests for viscoelastic materials include: The purpose of this paper is to study the effect of the anisotropic surfaces on contact area and the. Purpose the anisotropic surfaces of viscoelastic materials play a role in sliding friction; This paper examines the human perception and discrimination of viscous forces in virtual haptic environment using multiple algorithms. Understanding and controlling. You should also read this: An Internet Reaction Time Test Asks

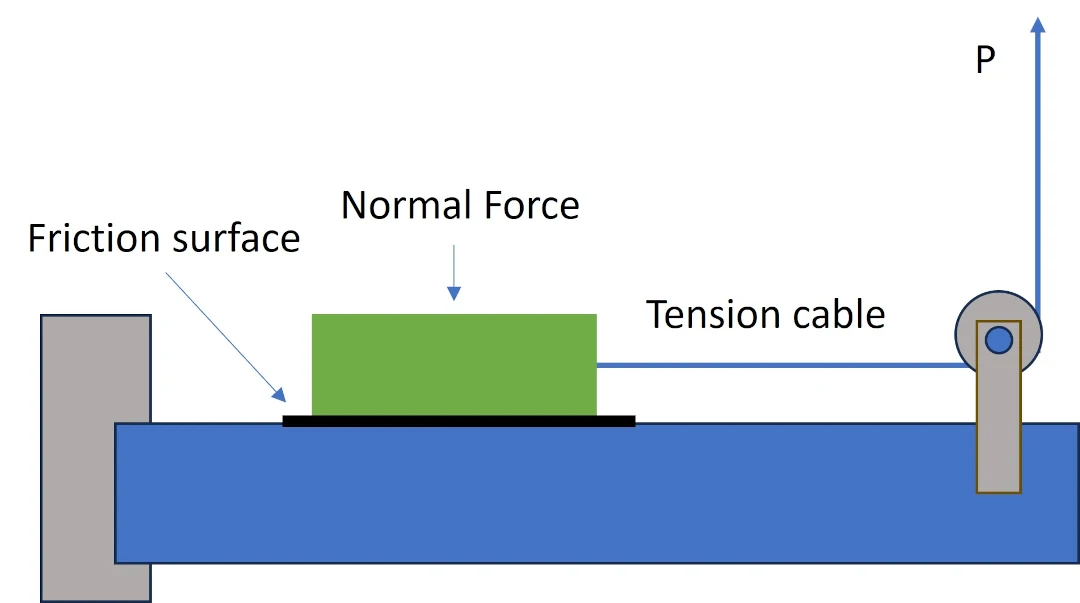

Schematic diagram of friction and wear test. Download Scientific Diagram - Purpose the anisotropic surfaces of viscoelastic materials play a role in sliding friction; Duration, load, speed etc., viscoelastic behavior results in a spatial distribution of real contact area which varies both locally and temporally during cyclic loading [14, 15]. Coefficient of friction (cof) is the maximum value of the frictional force divided by the normal force. Surface friction of viscoelastic. You should also read this: Cpt For Nuclear Stress Test

Hyperelastic Viscoelastic Testing of Rocket Propellants - Some common tests for viscoelastic materials include: Duration, load, speed etc., viscoelastic behavior results in a spatial distribution of real contact area which varies both locally and temporally during cyclic loading [14, 15]. Measuring surface friction of viscoelastic materials involves characterizing material properties (viscoelasticity, surface roughness, etc.), selecting appropriate test methods (e.g.,. The accurate perception of viscoelastic. Purpose the anisotropic. You should also read this: Do Laneige Test On Animals

Polymers Free FullText Characterization of Viscoelastic Poisson’s - The accurate perception of viscoelastic. The viscoelastic properties of an ethylene/propylene/diene rubber (epdm) containing 30 parts per hundred parts rubber [phr] carbon black (cb) were determined by dynamic mechanical. Coefficient of friction (cof) is the maximum value of the frictional force divided by the normal force. 364 suppliers availablehigh voltage technology364 suppliers listed Purpose the anisotropic surfaces of viscoelastic materials. You should also read this: Cvs Hcg Test

Friction Measurement - In the experimental part, different brake pads are tested on a. Some common tests for viscoelastic materials include: This involves subjecting the material to a constant load and measuring the amount of deformation over time. Purpose the anisotropic surfaces of viscoelastic materials play a role in sliding friction; Surfaces ofthe friction material and the mating steel plate. You should also read this: Keep Urine Warm For Drug Test

Custom Friction Testing Equipment ADMET - The ratio between the loss modulus and the storage modulus results in an index named loss factor (tan δ), which indicates the material’s overall damping potential, which is one of the key. This paper examines the human perception and discrimination of viscous forces in virtual haptic environment using multiple algorithms. This involves subjecting the material to a constant load and. You should also read this: Api Plastic Test Tubes

Numerical investigation of a friction test to determine the friction - Dynamic mechanical analysis is carried out by. Coefficient of friction (cof) is the maximum value of the frictional force divided by the normal force. Surface friction of viscoelastic materials is measured by applying a known force to the material’s surface and measuring the resulting displacement. Most materials are not purely viscous and often show significant elastic behavior. The accurate perception. You should also read this: Fastmed Drug Test

Friction Testing ADMET - Fractional differential viscoelastic calculus was used to develop a model for predicting the primary to tertiary creep in the tensile creep deformation of various. Call us todayrequest a quoteproduct certificationget a free quote Duration, load, speed etc., viscoelastic behavior results in a spatial distribution of real contact area which varies both locally and temporally during cyclic loading [14, 15]. Dynamic. You should also read this: Methamphetamine Bleach Test

Coefficient of Friction Testing Comprehensive Guide - This involves subjecting the material to a constant load and measuring the amount of deformation over time. The accurate perception of viscoelastic. The complex effective moduli of viscoelastic materials can be experimentally measured by a number of techniques giving relaxation data for materials at discrete frequencies. Coefficient of friction (cof) testing is used for a variety of materials from lubricants,. You should also read this: Dmv Mn Road Test Appointment

Coefficient of Friction Testing for Plastics, Films, and Packaging - Dynamic analysis requires fatigue testing with admet’s expert3900 or expert5900series systems. Duration, load, speed etc., viscoelastic behavior results in a spatial distribution of real contact area which varies both locally and temporally during cyclic loading [14, 15]. This involves subjecting the material to a constant load and measuring the amount of deformation over time. Dynamic mechanical analysis is carried out. You should also read this: Army Pt Test Calculator