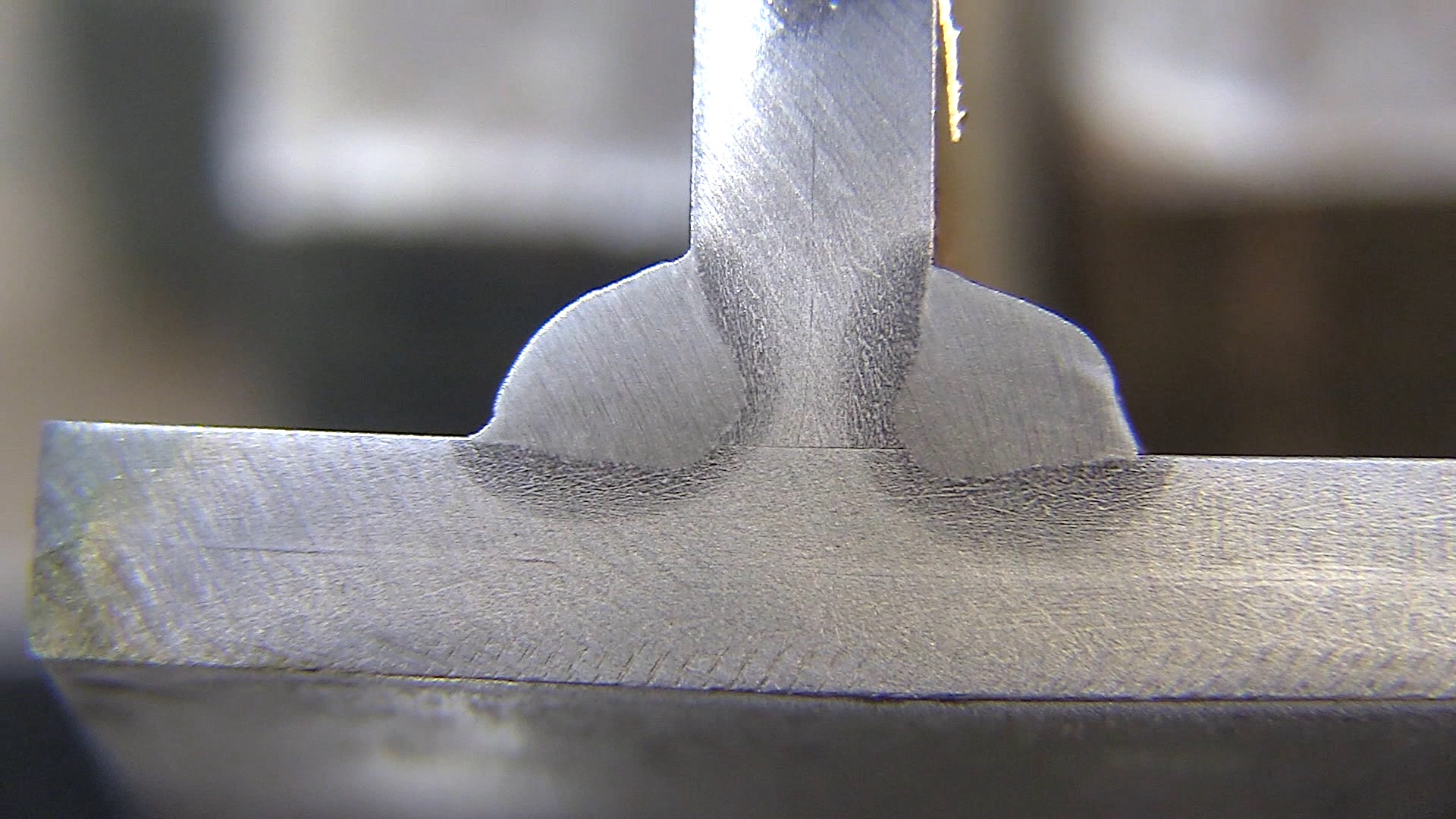

Cut Polish Etch, Testing Welds, Roll the Tank YouTube - Destructive weld testing evaluates the strength and characteristics of a completed weld by completing a physical destruction. The macro etch test can provide data for weld procedure qualification, failure analysis, routine quality checks, and welder qualification testing. Ensure strong, reliable welds with this effective testing technique used in metal fabrication. Learn about cut and etch weld testing, a vital method. You should also read this: Grol Practice Test

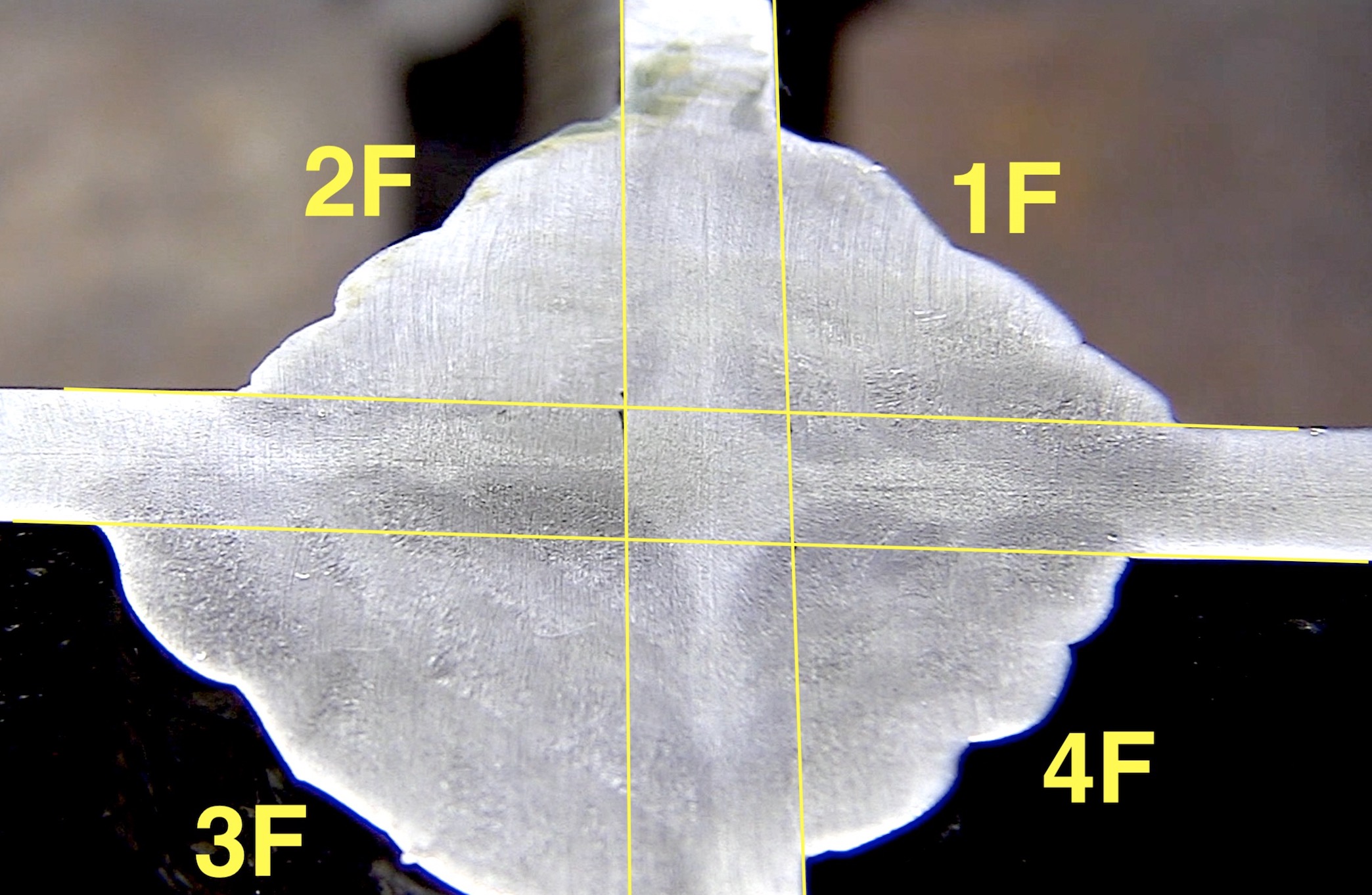

Weld nuggets at RSW parameters (a) 8 kA, 28 cycles, and 3 kN; (b) 8 - Destructive weld testing evaluates the strength and characteristics of a completed weld by completing a physical destruction. Experts then grind and polish the. Destructive weld testing, as the name suggests, involves the physical destruction of a completed weld to evaluate its strength and characteristics. A technician grinds, polishes, and etches the cut face of the sample using a chemical reagent,.. You should also read this: Test Of Malingering

Miller Multimatic 220 AC/DC Mig Welding Tips and Techniques - A technician grinds, polishes, and etches the cut face of the sample using a chemical reagent,. Destructive weld testing, as the name suggests, involves the physical destruction of a completed weld to evaluate its strength and characteristics. Our weld testing expertise ats often. Weld testing is integral to ensure the integrity and quality of. Experts then grind and polish the. You should also read this: Can I Take My Permit Test Online In Ohio

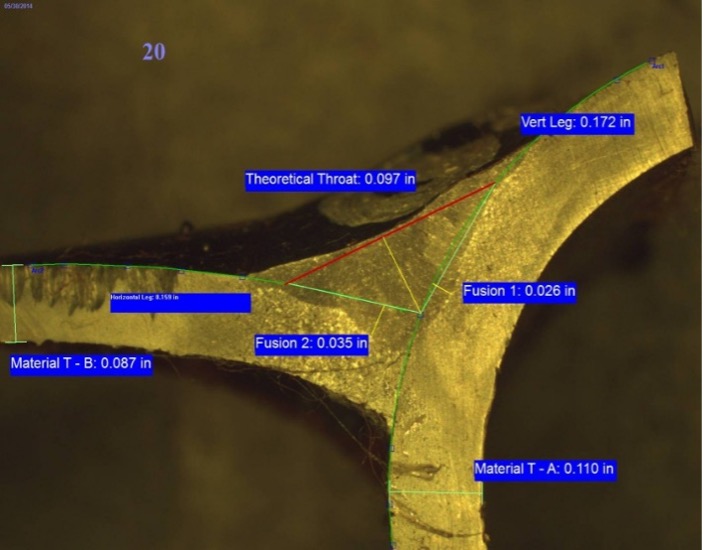

A Mig Welding Macro Etch Test - Our weld testing expertise ats often. Destructive weld testing, as the name suggests, involves the physical destruction of a completed weld to evaluate its strength and characteristics. The cut and etch test is a mechanical procedure for evaluating weld quality. Experts then grind and polish the. Ensure strong, reliable welds with this effective testing technique used in metal fabrication. You should also read this: Mold Testing Murfreesboro Tn

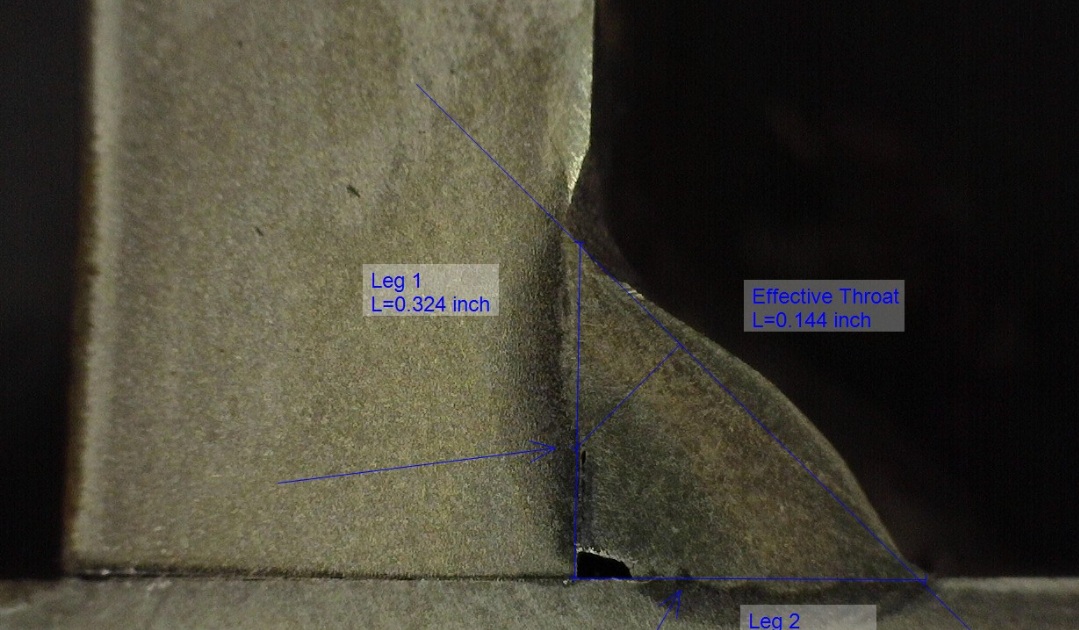

Macroetch Exam — Metallurgical Engineering Services - Destructive welding tests carry out a rigorous check to determine the quality of welds and other connections between metal parts. A technician grinds, polishes, and etches the cut face of the sample using a chemical reagent,. During these tests, engineers attempt to damage the. Destructive weld testing, as the name suggests, involves the physical destruction of a completed weld to. You should also read this: Tire Tread Test With Quarter

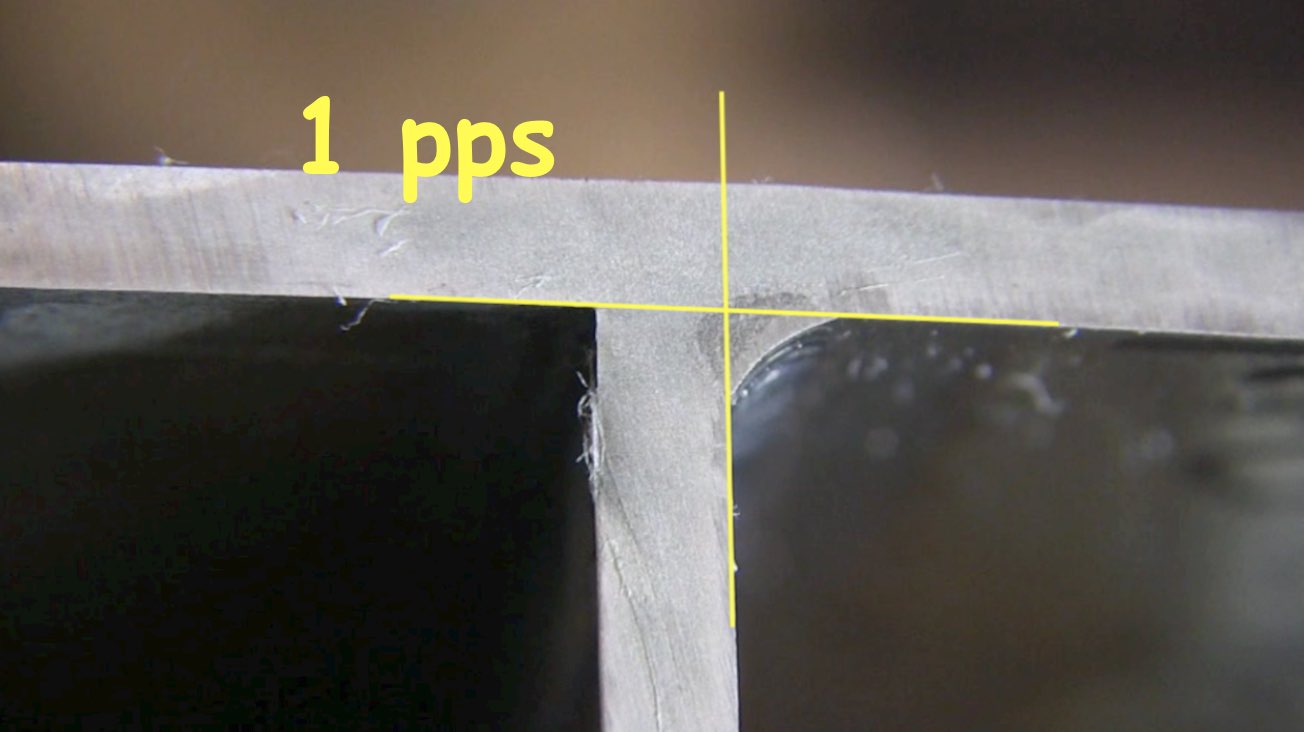

TIG Welding Techniques for Tee joints - Destructive weld testing evaluates the strength and characteristics of a completed weld by completing a physical destruction. The cut and etch test is a mechanical procedure for evaluating weld quality. Destructive weld testing, as the name suggests, involves the physical destruction of a completed weld to evaluate its strength and characteristics. Weld testing is integral to ensure the integrity and. You should also read this: Ap Psychology Unit 0 Test

Importance of Macro Etch Testing of Welds WELDING ANSWERS - Destructive weld testing, as the name suggests, involves the physical destruction of a completed weld to evaluate its strength and characteristics. The macro etch test can provide data for weld procedure qualification, failure analysis, routine quality checks, and welder qualification testing. The testing procedure is conducted to. Destructive weld testing evaluates the strength and characteristics of a completed weld by. You should also read this: Sperry Voltage Tester

Cut and Etch - Learn about cut and etch weld testing, a vital method for assessing weld quality. Our weld testing expertise ats often. During these tests, engineers attempt to damage the. The macro etch test can provide data for weld procedure qualification, failure analysis, routine quality checks, and welder qualification testing. Destructive weld testing, as the name suggests, involves the physical destruction of. You should also read this: Bls Skills Testing Checklist

Cut & Etch Weld Testing Modern Group - Weld testing is integral to ensure the integrity and quality of. Learn about cut and etch weld testing, a vital method for assessing weld quality. Etching of the metal surface is done to make visible the crystalline structure of the metal and to produce optical contrast between the various constituents. Our weld testing expertise ats often. The testing procedure is. You should also read this: Nevada Dmv Drivers Test Rubric

Macro etching test procedure for welded parts YouTube - The testing procedure is conducted to. Destructive weld testing, as the name suggests, involves the physical destruction of a completed weld to evaluate its strength and characteristics. Experts then grind and polish the. A technician grinds, polishes, and etches the cut face of the sample using a chemical reagent,. Destructive weld testing evaluates the strength and characteristics of a completed. You should also read this: Lsat In Person Testing