Cathodic Protection Testing Procedure Pdf - Protecting underground tanks from corrosion is easily achieved by the use of two commonly applied protection methods: Cathodic testing is required for. To ensure proper installation, monitoring and testing of cathodic protection of steel underground piping and underground propane tanks installed after august 25, 2010. Cathodic protection is the most common way to protect your underground propane tank or metallic. You should also read this: Ca Dmv Test For Seniors Over 70

Understanding Cathodic Corrosion Protection for Underground Tanks - Cathodic testing and documentation is required by nfpa 58 for underground tanks installed or serviced in 2011 and on. Installation and testing requirements include: Cathodic testing is required for. Cathodic protection is a critical method used to prevent corrosion in. Here’s a general overview of the essential tests and practices for underground propane tanks. You should also read this: Boots Pharmacy Blood Sugar Test

3 Steps to Meet Cathodic Testing Requirements P3 Propane Safety - Cathodic testing and documentation is required under nfpa 58, 2011 edition, for propane companies that have installed or serviced newer underground tanks. Without this protection, leaks can occur, resulting in personal. Nfpa 58 2011, section 6.6.6.1 for testing recommendations 1) test cathodic protection within 180. Protecting underground tanks from corrosion is easily achieved by the use of two commonly applied. You should also read this: Napa Block Tester Fluid

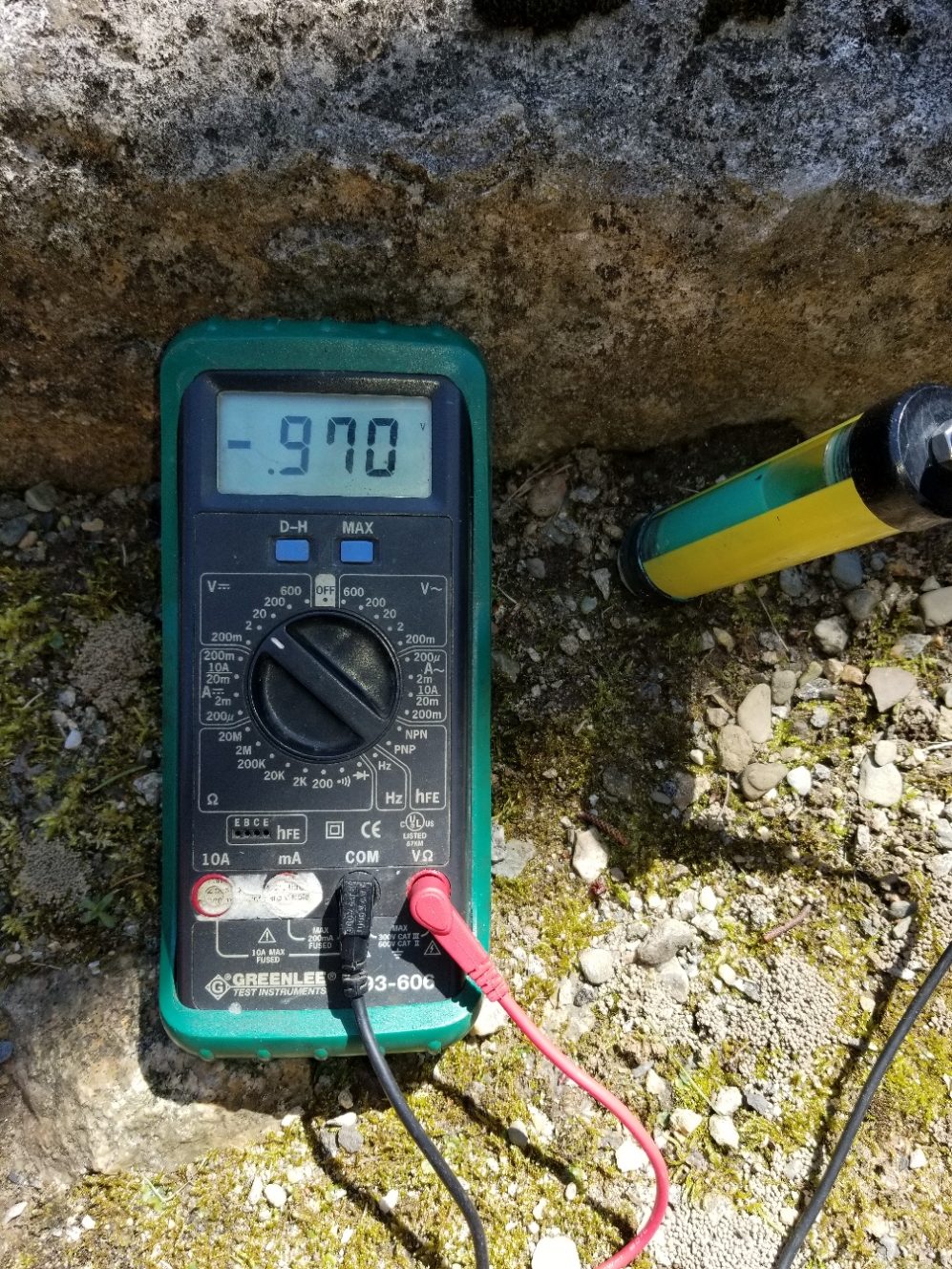

LP Industries Anode Test Kit - Cathodic protection is a critical method used to prevent corrosion in. Cathodic protection works by stopping. The two general types of cathodic protection systems are sacriicial and impressed current. Be sure to track cathodic testing compliance. Here’s a general overview of the essential tests and practices for underground propane tanks. You should also read this: Water Testing Digit

LP Industries Anode Test Kit - Cathodic protection is the most common way to protect your underground propane tank or metallic gas piping below grade from corrosion or rust. External coating and cathodic protection. Cathodic testing and documentation is required by nfpa 58 for underground tanks installed or serviced in 2011 and on. Sacriicial systems are used when the amount of current required for protection is. You should also read this: Holding Many Test Tubes Filled With Chemicals

Cathodic Protection for Underground Storage Tank (UST) Surface - Nfpa 58 2011, section 6.6.6.1 for testing recommendations 1) test cathodic protection within 180. Installation and testing requirements include: Cathodic testing and documentation is required under nfpa 58, 2011 edition, for propane companies that have installed or serviced newer underground tanks. Without this protection, leaks can occur, resulting in personal. Read this blog post to see if you are meeting. You should also read this: Fsa Ela Reading Practice Test

Cathodic tank Illustration Sippin Energy Products - Installation and testing requirements include: The national fire protection agency’s liquified petroleum gas code 58 requires routine cathodic testing requirements for underground propane tanks 2011 and newer. Cathodic protection is the most common way to protect your underground propane tank or metallic gas piping below grade from corrosion or rust. To ensure proper installation, monitoring and testing of cathodic protection. You should also read this: Nine Hole Peg Test Norms

US Tank Tech Inc. Underground Storage Tank Testing, Tank Scans/Sweeps - Cathodic testing is required for. Cathodic protection protection and testing for underground propane storage tanks. Installation and testing requirements include: External coating and cathodic protection. Nfpa 58 2011, section 6.6.6.1 for testing recommendations 1) test cathodic protection within 180. You should also read this: Nurseslabs Test Bank

Protecting buried propane tanks by testing & replacing sacrificial - Cathodic protection works by stopping. Underground propane tanks installed after 1/1/11 must have a cathodic protection system to help prevent corrosion of the tank. Cathodic protection is the most common way to protect your underground propane tank or metallic gas piping below grade from corrosion or rust. Cathodic testing and documentation is required by nfpa 58 for underground tanks installed. You should also read this: Testing Eggs Freshness

Chapter 1 Propane Tank Safety and Cathodic Protection Testing - External coating and cathodic protection. Cathodic protection protection and testing for underground propane storage tanks. Cathodic protection is a critical method used to prevent corrosion in. It is critical for propane companies to meet cathodic testing requirements set by the nfpa 58 code. Underground propane tanks installed after 1/1/11 must have a cathodic protection system to help prevent corrosion of. You should also read this: Road Test Definition